ពីអនុផលិតផលទៅជាស្រាដែលមានគុណភាពខ្ពស់៖ ក្រុមការងាររបស់អង្គការអូឌីស៊ីចុះទស្សនកិច្ចរោងចក្របិតស្រា «សម័យ»

ដោយរក្សាសកម្មភាពក្នុងការដកស្រង់សកម្មភាពនៃផលិតផលក្នុងស្រុក ដែលមានចីរភាពនៅកម្ពុជា នាថ្ងៃទី ២១ ខែមិថុនា ក្រុមការងាររបស់អង្គការទិន្នន័យអំពីការអភិវឌ្ឍ (អូឌីស៊ី)បានមកធ្វើទស្សនកិច្ចទៅកាន់ក្រុមហ៊ុន «សម័យ» ដែលជាក្រុមហ៊ុនបិតស្រារោម (Rum) ដែលមានមូលដ្ឋាននៅទីក្រុងភ្នំពេញ ដែលមានភាពខុសប្លែកគ្នា ពីអាជីវកម្មគ្រឿងអាល់កុលបែបប្រពៃណី។

ក្រុមការងារអូឌីស៊ីធ្វើទស្សនកិច្ចនៅកន្លែងបិតស្រា «សម័យ»។ រួបភាពដោយ Daniel Aboagye អ្នកស្រាវជ្រាវទិន្នន័យនៃអូឌីស៊ី។

ចាប់តាំងពីច្រកចូលទៅក្នុងកន្លែងបិតស្រា ក្រុមការងារអូឌីស៊ីបានជួបជាមួយលោក Daniel Pacheco និងលោក Antonio Lopez de Haro ដែលជាស្ថាបនិកនៃរោងចក្រផលិតស្រានេះ។ អ្នកទាំងពីរបានមកប្រទេសកម្ពុជាជិតមួយទសវត្សរ៍ ដើម្បីធ្វើអាជីវកម្ម ដែលមានភាពខុសប្លែកពីគេទាំងស្រុង។ កន្លែងបិតស្រានេះបានផ្តល់នូវដំណោះស្រាយថាមពល ប្រកបដោយចីរភាពរយៈពេលវែង សម្រាប់ប្រជាជននៅក្នុងតំបន់ ដែលភាគច្រើនមានឯកទេស ក្នុងការប្រើប្រាស់ថាមពលពន្លឺព្រះអាទិត្យ។ លោក Antonio វិញ បានចូលរួមក្នុងឧស្សាហកម្មបដិសណ្ឋារកិច្ច ដោយផ្តោតសំខាន់ទៅលើម្ហូបអាហារ និងភេសជ្ជៈ ហើយបានក្លាយជាអ្នកឯកទេសលើស្រាក្រឡុក និងភេសជ្ជៈគ្រប់ប្រភេទ។ ដោយសារតែពួកគាត់ចូលចិត្តលើការរៀនសូត្រដោយការអនុវត្តនោះ ពួកគាត់បានបង្កើតរោងចក្របិតស្រារោម នៅតំបន់អាស៊ីប៉ាស៊ីហ្វិក។

រោងចក្របិតស្រា «សម័យ» គឺជា «ហាងបិតស្រារោម ដំបូងគេបង្អស់របស់ប្រទេសកម្ពុជា»។ ប្រាកដណាស់ មុនពេល Daniel និងAntonio ដែលជាជនជាតិវ៉េណេស៊ុយអេឡាពីរនាក់ បានមកដល់ប្រទេសកម្ពុជានេះ ស្រារោម គឺជាស្រាមានតម្លៃសម្រាប់អតិថិជនក្នុងស្រុកភាគច្រើន។ ខណៈពេលដែលពួកគាត់រស់នៅប្រទេសកម្ពុជា ហើយបានចូលរួមនៅក្នុងវិស័យធុរកិច្ចដទៃទៀតជាច្រើន លោក Pacheco និងលោក Lopez de Haro បានខិតខំប្រឹងប្រែងស្វែងរកស្រារោម ដែលមានគុណភាពល្អ ដែលជាភេសជ្ជៈល្បីមួយប្រភេទ ផលិតនៅក្នុងស្រុកកំណើតរបស់ពួកគាត់។ ក្នុងពេលជាមួយគ្នា ពួកគាត់ទាំងពីរអ្នក បានឃើញពីស្ថានភាពអាកាសធាតុល្អឥតខ្ចោះ សម្រាប់ការដាំអំពៅដែលកម្ពុជាផ្តល់ឱ្យ។ ដោយសារការចាប់អារម្មណ៍នេះ Daniel និងAntonio បានសម្រេចចិត្តស្រាវជ្រាវបន្ថែម។ នៅក្នុងប្រទេសកម្ពុជា អំពៅភាគច្រើនត្រូវបានគេកៀបយកទឹក ឬជាចំណីរបស់គោក្របី។ ទោះបីជាអំពៅក៏ត្រូវបានគេប្រើដើម្បីផលិតស្ករសក៏ដោយ ឧស្សាហកម្មស្ករនៅក្នុងប្រទេសមិនអាចមានបច្ចេកវិទ្យាខ្ពស់ទេ។ នេះមានន័យថា ខណៈពេលដែលត្រូវបានកែច្នៃទៅជាស្ករស កាកសំណល់នៃអំពៅបានបន្សល់ទុកកម្រិតជាតិស្ករក្នុងបរិមាណច្រើន។ កាកសំណល់ដែលសំបូរដោយជាតិស្ករនេះ ពិតជាអ្វីដែល Daniel និងAntonio ចង់បាន។ ជាទូទៅ ត្រូវបានគេស្គាល់ថាជា «molasses», «កាកសំណល់» នៃផលិតកម្មស្ករ គឺជាវត្ថុធាតុដើមសំខាន់ សម្រាប់ផលិតស្រារោម នៅក្នុងប្រទេសរបស់ពួកគាត់។

ជាមួយនឹងវត្ថុធាតុដើមនេះ Daniel និងAntonio មានការភ្ញាក់ផ្អើលយ៉ាងខ្លាំង ដែលដឹងថា គ្មាននរណាម្នាក់មើលឃើញថា វាជាឱកាសអាជីវកម្មទេ។ គំនិតនៃការផ្លាស់ប្តូរកាកសំណល់ដែលមានគុណភាពល្ធនេះ ទៅជាស្រារោមដែលមានគុណភាពខ្ពស់ បានក្លាយជាគ្រឹះនៃអាជីវកម្មថ្មីរបស់ពួកគាត់ទាំងពីរ។ ជាមួយនឹងប្រពៃណីជនជាតិវ៉េណេស៊ុយអេឡា ដែលមានអាយុច្រើនសតវត្សរ៍ ក្នុងការផលិតភេសជ្ជៈមានជាតិស្ករដែលមានគុណភាពខ្ពស់ អ្នកជំនួញបានសម្រេចចិត្តបើកដំណើរការសហគ្រាសដំបូងរបស់ខ្លួន នៅក្នុងប្រទេសកម្ពុជា។ ផ្ទុយទៅនឹងក្រុមហ៊ុនជាច្រើនទៀតដែលកំពុងដំណើរការ គំរូអាជីវកម្មស្រដៀងគ្នា រោងចក្របិតស្រា «សម័យ» បានចាត់ទុកខ្លួនពួកគាត់ជាក្រុមហ៊ុនមានការទទួលខុសត្រូវផ្នែកសង្គម ដែលផលិតផលិតផលមានគុណភាពខ្ពស់ដោយប្រជាជននៅក្នុងតំបន់។ នៅពេលអង្គការអូឌីស៊ី បានចុះទស្សនកិច្ច យើងពិតជាបានឃើញអ្វីដែលពួកគាត់និយាយមែន។

ចាប់ពីដំណាក់កាលដំបូងនៃការជ្រើសរើសប្រភេទជាតិស្ករ ដែលមានគុណភាពល្អបំផុតពីអ្នកផលិតក្នុងស្រុក ក្រុមហ៊ុនមិននាំចូលវត្ថុធាតុដើមពីបរទេសទេ ប៉ុន្តែបានសហការជាមួយកសិករខ្មែរ។ ក្រៅពីផលិតផលដែលទទួលបានពានរង្វាន់ «ស្រារោមមាស» ដែលជាផលិតផលស្តង់ដាររបស់ក្រុមហ៊ុននេះ «ស្រារោមម្រេចកំពត» បានទទួលនូវកេរ្តិ៍ឈ្មោះដ៏ល្បីល្បាញ ព្រមទាំងទទួលបានរង្វាន់ ពីការប្រកួតប្រជែងអន្តរជាតិផងដែរ។ ជាការពិត ដោយមានរសជាតិហឹរប្លែកពីគេ ផលិតផលដំបូងបំផុតនេះលើកកម្ពស់ការដាំដុះប្រកបដោយទំនួលខុសត្រូវ ក្នុងខេត្តកំពត ដោយដាក់បញ្ចូល ម្រេច ខេត្តកំពត ដែលដាំដុះដោយចីរភាពពី La Plantation ទៅក្នុងរូបមន្តរបស់វាតាំងពីដំបូង។

ការកាច់មេ (Fermentation) - ដំណើរការទី ២ ដែលទាក់ទងនឹងស្ករ និងមេដំបែ ធ្វើប្រតិកម្មនៅក្នុងធុងដែក។ ដំណាក់កាលបន្ទាប់ ដើម្បីទទួលបានអាល់កុលរួចរាល់សម្រាប់ការបិតស្រា ដំណើរការនេះគួរតែត្រូវបានគ្រប់គ្រងដោយប្រុងប្រយ័ត្ន ដោយអ្នកជំនាញដែលមានឯកទេស និងការបណ្តុះបណ្តាលពិសេស។ នៅ «សម័យ» លោក David ជាវិស្វករគីមី ជនជាតិវ៉េណេស៊ុយអេឡា កំពុងធ្វើការជាមួយ Darachampich ដែលជាអ្នកឯកទេសដំបូងបង្អស់ផ្នែកស្រារោមរបស់ប្រទេសកម្ពុជា ដែលបានបញ្ចប់ការសិក្សាពី វិទ្យាស្ថានបច្ចេកវិទ្យាកម្ពុជា (ITC) ។ ដោយសារចក្ខុវិស័យចម្បងរបស់សហគ្រាស គឺផលិត ផលិតផលក្នុងស្រុកដែលមានគុណភាពខ្ពស់ ក្រុមហ៊ុនពិតជាមានចំណាប់អារម្មណ៍ខ្លាំងណាស់ ក្នុងការជ្រើសរើសបុគ្គលិកក្នុងតំបន់ និងបណ្តុះបណ្តាលបុគ្គលិកផ្ទាល់ខ្លួន។ ដើម្បីសម្រេចគោលបំណងនេះ «សម័យ» បានបង្កើតកិច្ចសហការយូរអង្វែង ជាមួយវិទ្យាស្ថានបច្ចេកវិទ្យាកម្ពុជា (ITC) ក្នុងការជ្រើសរើសវិស្វករចំណីអាហារ ដែលទើបតែបញ្ចប់ការសិក្សា និងផ្តល់ការហាត់ការងារសម្រាប់និស្សិតដែលកំពុងសិក្សា។

ដោយឡែក រឿងរ៉ាវផ្ទាល់ខ្លួនរបស់អ្នកធ្វើការងារម្នាក់ទៀត ដែលទទួលខុសត្រូវ ក្នុងការត្រួតពិនិត្យដំណើរការចម្រាញ់ក៏គួរឱ្យចាប់អារម្មណ៍ផងដែរ។

បញ្ញា បានចាប់ផ្តើមធ្វើការជាលើកដំបូង នៅ«សម័យ» ជាសន្តិសុខ។ ទោះជាយ៉ាងណាក៏ដោយ គាត់មានឆន្ទៈយ៉ាងខ្លាំង ក្នុងការចូលរួមក្នុងដំណើរការជាសមាជិកក្រុម ហើយអ្នកគ្រប់គ្រងបានសម្រេចចិត្តផ្តល់ឱ្យគាត់នូវការបណ្ដុះបណ្ដាល និងអនុញ្ញាតឱ្យគាត់ចូលរួមនៅក្នុងអ្វីដែលគាត់ចង់បាន។

នៅពេលនេះ លោក បញ្ញា ជាអ្នកត្រួតពិនិត្យមើលការបិតស្រាទាំងអស់របស់«សម័យ» ដែលបានធ្វើឡើងនៅក្នុងឆ្នាំង ច្នៃដោយដៃ ដែលមានរាងដូចខ្លោក នាទសវត្សរ៍ឆ្នាំ ១៨០០។

បន្ទាប់ពីការបិតស្រារួចមក វីស្គីដែលនឹងក្លាយជាស្រារោម ត្រូវបានគេកាត់បន្ថយអាល់កុលមកត្រឹម ៦៥ ភាគរយ ហើយត្រូវបានដាក់បញ្ចូលទៅក្នុងធុងឈើ ដើម្បីឱ្យមានការវិវត្ត។ នេះគឺជាកន្លែងដែលវាទទួលបានរសជាតិឆ្ងាញ់ និងតែមួយគត់របស់វា។ ស្រារោមរសជាតិម្រេចកំពត ឈានដល់ការច្រកដាក់ដប។ ស្រារោមពិសេសនេះ អាចទទួលទានបាន ដែលមានម្រេចខេត្តកំពត ជាសមាសធាតុផ្សំសំខាន់។

ធុងរក្សាអាយុ។ រូបភាពដោយ កន្លែងបិតស្រា «សម័យ» និង Daniel Aboagye អ្នកស្រាវជ្រាវទិន្នន័យនៃអូឌីស៊ី។

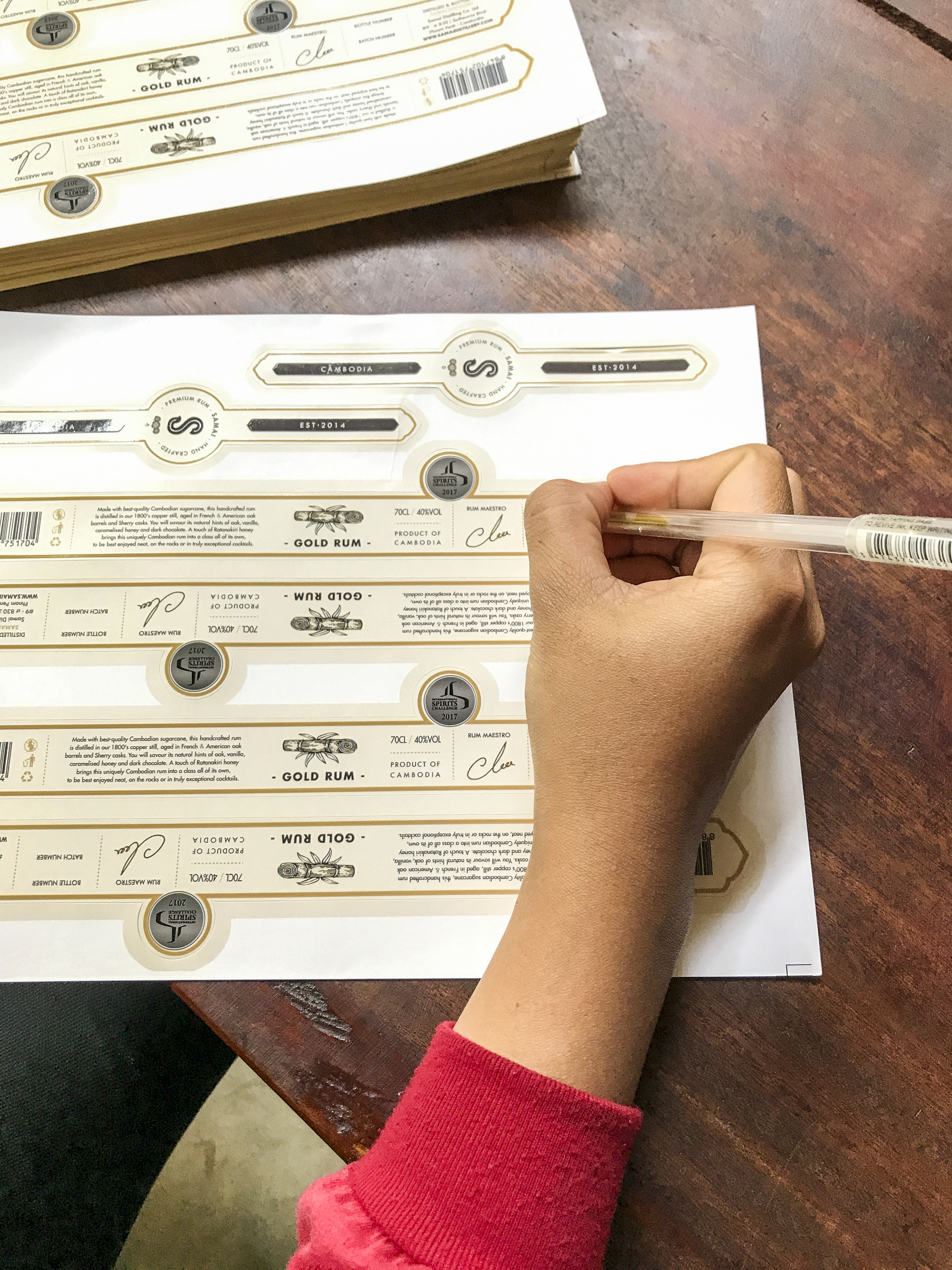

បន្ទាប់ពីរក្សាសារធាតុបានអាយុយ៉ាងហោចណាស់ពីរឆ្នាំនៅក្នុងធុង អ្នកជំនាញរបស់ «សម័យ» បានច្រោះយកសំណាកល្អបំផុត ដែលនាំយកអាល់កុលមកត្រឹម ៤០ ភាគរយ មុនពេលច្រកដាក់ចូលដប។ ចុងបញ្ចប់ ស្លាកសម្គាល់ត្រូវបានបិទលើដប ហើយបានត្រៀមខ្លួនរួចរាល់ ដើម្បីដឹកជញ្ជូនទៅកាន់អតិថិជន។

ការច្រកស្រារោមចូលក្នុងដប។ រូបភាពដោយ កន្លែងបិតស្រា «សម័យ»។

ដូចដែលយើងបានឃើញ ទោះបីជាផលិតកម្មស្រារោមមួយចំនួន នៅតែមានលក្ខណៈដូចគ្នានឹងដំណើរការនៅអាមេរិកឡាទីន ក្រុមការងាររបស់ «សម័យ» កំពុងខិតខំប្រឹងប្រែងដើម្បីកែលម្អស្នាដៃរបស់ពួកគេ។ លើសពីនេះទៅទៀត ដោយសារតែឈ្មោះក្រុមហ៊ុននេះពាក់ព័ន្ធទៅនឹងពាក្យខ្មែរ ដែលមានន័យថាសម័យទំនើប ដែលកំពុងសម្លឹងឆ្ពោះទៅរកអនាគតនោះ អូឌីស៊ីរីករាយនឹងឃើញថា តាមរយៈការបង្កើតភេសជ្ជៈគុណភាពល្អ ជាលើកដំបូងរបស់ប្រទេស ពីធនធានក្នុងស្រុក ការជួលបុគ្គលិកក្នុងស្រុក និងអប់រំប្រជាជនខ្មែរ។ «សម័យ» មានមោទនភាពដែលបានក្លាយជា ស្រារោម ដែលមានគុណភាពល្អ ដំបូងគេបង្អស់នៅក្នុងប្រទេសកម្ពុជា ដោយបានដាក់ប្រទេសកម្ពុជា នៅក្នុងផែនទីនៃស្រារោមដ៏ល្អបំផុតមួយចំនួននៅលើពិភពលោក ខណៈពេលកំពុងអភិវឌ្ឍឧស្សាហកម្មក្នុងស្រុក។